ELL ESS ENGINEERING P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to ELL ESS ENGINEERING P.LTD.

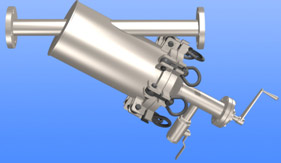

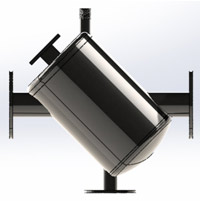

Brush Filter

The liquid enters the top inlet nozzle and the flow & the filtration takes place from in to out. During filtration operation the solids are deposited on the inside surface of the filter media. Since the brush is continuously rotating, which prevents the solids from clogging the filtration area, the regeneration of the filtration area is continuous. During filtration operation due to continuous cleaning the concentration of solids in the liquid inside the media increases, continuously it will increase the differential pressure between inlet and outlet. When the desired ∆p set in the PLC system is reached, the bottom butterfly valve opens to discharge the concentrated slurry till the ∆p comes back to the original level. The discharge operation is very fast and its frequency depends upon the percentage of solid load in the inlet.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.